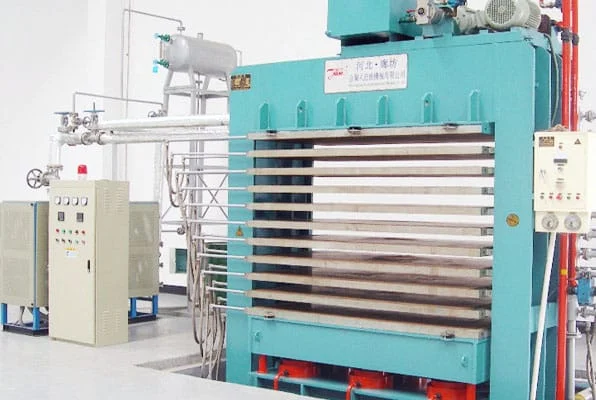

Electric Thermal Oil Boiler Heater for Hot Press Machines – 10-4200 kW

Our electric thermal oil (hot oil) boiler heater delivers high-efficiency heating (≥ 98%) for hot-press applications in new materials, plastics, non-wovens and laminating lines. Customisable from 10 to 4200 kW, with PLC/PID control, 380 V/50Hz standard (or custom), and reliable all-welded construction for stable process heat and long service life.

Get Your Customised Product

🔥 Ruiyuan Electrically Heated Organic Heat Carrier Boiler — 10 to 4200 kW | Multi-Zone Heating | PLC Controlled

Product Overview

The Ruiyuan Electrically Heated Organic Heat Carrier Boiler represents the pinnacle of industrial heating technology, delivering precision zoned thermal management through advanced closed-loop circulation. Engineered for applications demanding exact temperature control, this system utilizes high-performance thermal oil and sophisticated PLC technology to provide uniform heat distribution across multiple independent zones. With capacities spanning from 10 to 4200 kW, this boiler system outperforms traditional steam solutions in efficiency, safety, and customization capabilities.

Key Benefits for Buyers

✅ Advanced Multi-Zone Technology — Independent temperature control across multiple sections within a single unified system

✅ Emission-Free Operation — Electric heating completely eliminates combustion emissions and environmental contaminants

✅ Premium Energy Efficiency — ≥98% thermal efficiency significantly reduces operational costs and energy waste

✅ Unmatched Precision Control — Advanced PLC/PID system guarantees ±1°C accuracy for critical processes

✅ Comprehensive Power Range — 10-4200 kW capacity ensures perfect matching to your specific thermal requirements

✅ Military-Grade Construction — All-welded boiler body built for extreme industrial environments and long-term reliability

✅ Total Customization — Bespoke engineering solutions for even the most complex heating challenges

Product Features

Power Spectrum: 10-4200 kW (completely customizable)

Heating Technology: Advanced electric heating with premium organic heat transfer oil

Efficiency Rating: ≥98% thermal efficiency with superior heat retention

Control Precision: PLC/PID system with ±1°C accuracy guarantee

Structural Integrity: All-welded construction (stainless steel/carbon steel options)

Heating Innovation: True multi-zone independent temperature management

Electrical Compatibility: 380V/50Hz standard (full custom configurations available)

Circulation Excellence: High-temperature industrial pumps for flawless performance

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Electrically Heated Organic Heat Carrier Boiler |

| Heating Medium | Premium Organic Heat Transfer Oil |

| Power Output | 10-4200 kW (Fully Customizable) |

| Thermal Efficiency | ≥98% |

| Control System | Advanced PLC/PID Precision Control |

| Construction | Heavy-Duty All-Welded Boiler Body |

| Materials | Stainless Steel / Carbon Steel |

| Standard Voltage | 380V/50Hz (Customizable) |

| Special Feature | Multi-Zone Independent Temperature Control |

Working Principle

This sophisticated system operates through precision electric heating elements that transfer thermal energy to high-grade organic heat carrier oil within a completely sealed, pressurized circulation circuit. Industrial-grade high-temperature pumps efficiently distribute the heated oil through strategically partitioned zones, each maintaining completely independent temperature profiles. The intelligent PLC-controlled system continuously monitors, adjusts, and optimizes each zone in real-time, ensuring absolute thermal precision across the most complex industrial processes while maintaining maximum safety and operational efficiency.

Applications & Industries

🏭 Chemical & Petrochemical Processing — Multi-zone reactor heating for critical temperature-sensitive reactions

🛠 Industrial Drying Solutions — High-capacity tunnel ovens and drying systems for continuous operation

💡 Advanced Materials Manufacturing — Precision zoned roller heating for plastics and nonwovens production

🔧 Asphalt & Construction Materials — Consistent high-temperature maintenance in storage and mixing systems

🏗 Food & Beverage Processing — Clean, contaminant-free high-temperature heating solutions

🔬 Pharmaceutical Production — Sterile, precise thermal management for sensitive manufacturing processes

Why Choose Ruiyuan

With our foundation established in 2008 and operating from a 23,000 m² state-of-the-art manufacturing facility, Ruiyuan brings over 160 industry certifications and qualifications to every project. Our uncompromising commitment to quality, innovation, and customer satisfaction makes us the global partner of choice for industrial thermal solutions. From initial design to worldwide after-sales support, we deliver excellence at every stage.

Documentation & Support

📄 Comprehensive Product Datasheet (Available on Request)

📄 Full Certification Package (Available on Request)

📄 Detailed Operation & Maintenance Manual (Provided with System)

🔧 24/7 Global Technical Support & Worldwide Spare Parts Service

Request Custom Solution

Provide your specific zoned heating requirements including temperature profiles, thermal capacity needs, and process applications. Our senior engineering team will develop a fully tailored organic heat carrier system precisely optimized for your industrial requirements.

📞 Contact Our Thermal Engineering Experts

WhatsApp: +86 191 0610 1572

Email: sabbir@cnryan.com

🎯 Ready to transform your industrial heating? Contact us today for a comprehensive, customized thermal solution!

Related products

-

Thermal oil boiler

Explosion-Proof Electric Heating Thermal Oil Boiler – 10-4200 kW

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Dryers – 10-4200 kW