Vacuum Cleaning Furnace for Cleaning Screws — Automatic Polymer Removal Oven

The Ruiyuan Vacuum Cleaning Furnace for Cleaning Screws offers a clean, safe, and automated method for removing polymer and carbon residues from extruder screws and tools. With electrical heating, −0.085 MPa vacuum, and 450 °C high-temperature cleaning, it ensures thorough residue removal without damaging metal parts. Fully automated PLC control enables consistent, efficient, and low-maintenance operation.

Get Your Customised Product

🔩 High-Efficiency Vacuum Pyrolysis Cleaning Furnace for Extruder Screws | Zero-Wear Polymer Removal System

Product Overview

The Ruiyuan Vacuum Pyrolysis Cleaning Furnace for Extruder Screws is the dedicated, automated solution for complete removal of plastic and polymer residues from extruder screws, barrels, filters, and tooling. Utilizing high-precision electric heating within a sealed vacuum environment, it executes a fully controlled three-phase cleaning cycle (Melting $\rightarrow$ Pyrolysis $\rightarrow$ Controlled Oxidation). This advanced system guarantees residue-free screw surfaces without mechanical abrasion, chemical corrosion, or the risk of warping associated with high-temperature ovens. Maximize screw lifespan, optimize melt flow, and minimize production downtime across all plastics and fiber processing lines.

Key Benefits for Buyers (Focus on Tooling Protection and Production)

✅ Screw Longevity Guaranteed: Cleans without the mechanical stress or thermal damage of manual scraping or open-flame systems, significantly extending screw lifespan.

✅ Maximized Extrusion Quality: Achieves perfectly clean, smooth screw flights, ensuring optimal melt flow, consistent throughput, and zero black-speck contamination.

✅ Fully Automated & Hands-Free: PID/PLC controlled multi-phase cycle requires no continuous supervision, freeing up maintenance personnel.

✅ Energy and Cost Savings: Features High Thermal Efficiency and a fast cycle time, reducing energy consumption and operational costs.

✅ Safe & Compliant Operation: Closed vacuum system minimizes airborne emissions and uses an optional gas scrubber for safe, environmentally sound exhaust processing.

✅ Precision Reliability: $\pm 1^{\circ}\text{C}$ temperature accuracy prevents metal degradation and guarantees consistent, repeatable results across various polymer types.

Product Features (Engineering Specifications)

| Feature | Specification / Benefit |

| Primary Use | Extruder Screws, Barrels, Melt Filters, Extrusion Dies |

| Cleaning Method | Vacuum Pyrolysis (Non-abrasive, non-chemical) |

| Ultimate Vacuum | −0.085 MPa (Enables low-temperature polymer decomposition) |

| Maximum Temperature | $450^{\circ}\text{C}$ (Optimized for polymer burnout) |

| Control System | PID/PLC Logic with real-time Thermocouple Monitoring |

| Cleaning Cycle | Fully Automatic (Melting $\rightarrow$ Pyrolysis $\rightarrow$ Oxidation) |

| Construction | All-welded Stainless Steel Vacuum Chamber (High durability) |

| Safety System | Over-temperature Interlock, Vacuum Pressure Interlock, Automatic Air Purge |

| Efficiency | High Efficiency, Low Energy Consumption (Advanced Insulation) |

Technical Specifications (Targeting High-Value Keywords)

| Parameter | Specification | SEO Keywords Targeted |

| Product Name | Industrial Vacuum Pyrolysis Furnace for Extruder Screw Cleaning | industrial extruder screw cleaning equipment |

| Ultimate Vacuum | $-0.085 \text{ MPa}$ | vacuum plastic residue removal system |

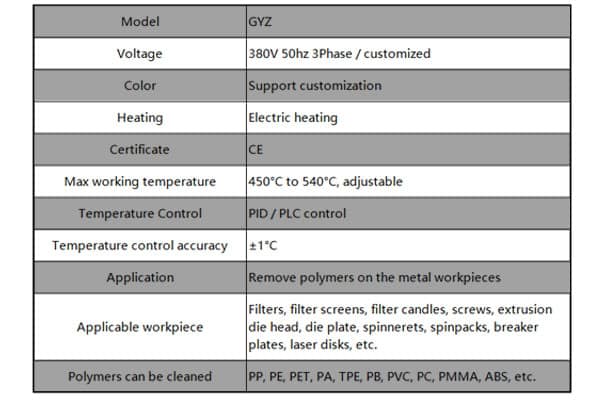

| Temperature Control | PID/PLC with $\pm 1^{\circ}\text{C}$ Accuracy | precision temperature polymer cleaning |

| Standard Voltage | 380 V / 50 Hz (Customization Available) | custom industrial furnace voltage |

| Structure / Material | All-welded Stainless Steel Body (Vacuum-Tight) | stainless steel vacuum furnace B2B |

| Typical Applications | Single/Twin Screws, Injection Moulding Components, Filter Packs | twin-screw extruder cleaning machine |

| Control & Monitoring | Automatic 3-Phase Process Control | automated polymer cleaning process |

Working Principle: Protecting Your Investment

The controlled Ruiyuan process systematically removes residue while isolating the screw from harsh conditions:

I. Melting Phase: The screw is gradually heated to $\mathbf{320^{\circ}\text{C}}$ under deep vacuum. Bulk polymer melts rapidly and safely drains into the collection tray, reducing the workload for the subsequent phase.

II. Pyrolysis Phase: Remaining, tightly bonded polymer is decomposed and vaporized at low pressure. The vacuum prevents combustion and draws out gases, which are treated by the scrubber system for safe discharge.

III. Oxidation Phase: A carefully limited amount of oxygen is introduced to oxidize the remaining thin film of carbon residue, resulting in a smooth, bright, and perfectly clean screw surface ready for re-installation.

Applications & Case Scenes (Solving Industry Problems)

- 🏭 Extrusion Lines: Essential for single and twin extruder screw cleaning, maintaining critical flight clearances and surface finish.

- 🛠 Injection Molding: Precise cleaning for barrels, nozzles, and complex hot runner systems without damaging micro-components.

- 💡 Chemical Fiber Production: Gentle, controlled cleaning for sensitive spinnerets and metering pumps used in PET, PP, and PA processing.

- 🔧 Maintenance & Service Workshops: Provides a standardized, high-capacity, and environmentally responsible cleaning solution for various plastic parts.

Request a Custom Engineering Quote

Optimize your extrusion line’s performance and protect your most valuable tooling. To receive a detailed technical specification and quote, please provide:

- Maximum Screw Dimensions (Length and Diameter)

- Polymer Contaminants (e.g., PET, Nylon, PVC, ABS)

- Required Cleaning Frequency/Capacity

- Installation Space and Utility Requirements

📞 Contact Technical Sales for a Specialized Solution Design

WhatsApp: +86-19106101572 | Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Cleaning Filters — Fully Automatic Polymer Removal Furnace

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Die Head Cleaning – Automated Industrial Cleaning System