Vacuum Pyrolysis Cleaning Furnace for Cleaning Spinnerets in Nonwovens Industry — Fully Automatic Polymer Removal System

The Ruiyuan Vacuum Pyrolysis Cleaning Furnace is designed for precision cleaning of spinnerets used in the nonwoven and chemical fiber industries. With −0.085 MPa vacuum, 450 °C maximum temperature, and fully automated electric heating control, it safely removes polymer, carbon, and residue buildup without damaging delicate holes. High efficiency, low energy use, and accurate temperature regulation ensure superior cleanliness and productivity.

Get Your Customised Product

🔹 Advanced Vacuum Pyrolysis Cleaning Furnace for Nonwoven Spinnerets | Zero-Stress Polymer Removal

🧭 Product Overview

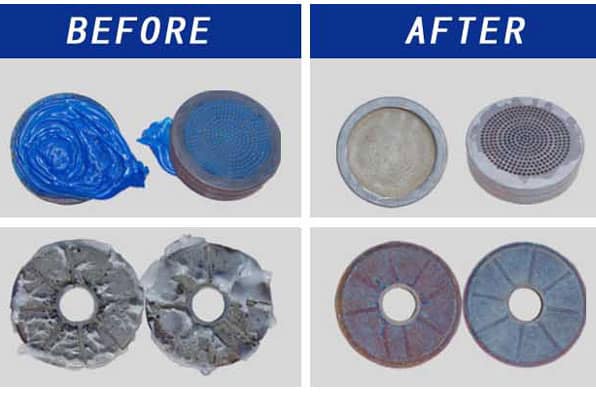

The Advanced Vacuum Pyrolysis Cleaning Furnace is engineered for precision cleaning of nonwoven spinnerets, polymer filters, and extrusion dies. It combines electric heating technology with a deep vacuum chamber, delivering a fully automated three-phase cleaning process — Melting → Pyrolysis → Controlled Oxidation — to ensure total polymer removal without deformation or surface stress.

Purpose-built for the nonwoven and meltblown fiber industry, this system guarantees micro-hole integrity, superior fiber consistency, and maximum machine uptime. With PLC/PID intelligent control and ±1 °C temperature accuracy, it achieves 100% residue-free cleaning safely, efficiently, and sustainably.

💡 Key Benefits for Buyers

-

✅ Spinneret Integrity Guaranteed — Designed specifically for nonwoven spinnerets and precision molds to eliminate micro-damage and hole deformation.

-

✅ Fully Automatic & Hands-Free — PLC-controlled cleaning sequence requires no manual scraping or supervision.

-

✅ Certified Precision — Maintains an ultimate vacuum of −0.085 MPa and ±1 °C temperature accuracy for delicate parts.

-

✅ Maximum Uptime — Short cycle time reduces production downtime and supports faster die changes.

-

✅ Eco-Friendly Operation — Optional dual-stage scrubber ensures emission-free and compliant exhaust treatment.

-

✅ Energy Efficient — Advanced ceramic fiber insulation achieves ≥98% thermal efficiency, minimizing operating costs.

⚙️ Product Features

| Feature | Specification / Benefit |

|---|---|

| Primary Use | Nonwoven spinneret, filter, and die head cleaning (PET, PP, PA, etc.) |

| Cleaning Method | Vacuum pyrolysis — protects precision parts from stress and warping |

| Ultimate Vacuum | −0.085 MPa — enables low-temperature polymer vaporization |

| Maximum Temperature | 450 °C — optimized for safe polymer decomposition |

| Temperature Control | PLC/PID regulation with ±1 °C accuracy |

| Thermal Efficiency | ≥98% — best-in-class energy conservation |

| Construction | All-welded stainless steel vacuum chamber with polymer collection tray |

| Safety System | Over-temperature interlock, vacuum-loss alarm, automatic air purge |

| Customization | Chamber size, voltage, and power rating customizable to project needs |

📊 Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Industrial Vacuum Pyrolysis Cleaning Furnace |

| Cleaning Process | Melting → Pyrolysis → Controlled Oxidation |

| Temperature Range | Ambient to 450 °C |

| Ultimate Vacuum | −0.085 MPa |

| Temperature Control | PLC/PID control with ±1 °C precision |

| Thermal Efficiency | ≥98% |

| Structure / Material | All-welded stainless-steel vacuum chamber |

| Standard Voltage | 380 V / 50 Hz (customizable for global markets) |

| Typical Applications | Nonwoven spinnerets, extrusion die heads, polymer filters |

| Certification | QA/QC verified — CE and D-Class standards available upon request |

🔬 Working Principle

I. Melting Phase (Gentle Start)

Spinnerets and filters are gradually heated under vacuum to 320 °C, melting and draining most of the polymer residues before decomposition begins.

II. Pyrolysis Phase (Core Removal)

Remaining polymers are vaporized and chemically decomposed under a −0.085 MPa vacuum. This low-oxygen environment prevents oxidation and ensures clean vapor exhaust via the dual-stage scrubber system.

III. Controlled Oxidation Phase (Final Polish)

A precise airflow is introduced to oxidize residual carbon into ash, leaving a bright, residue-free surface ready for production use.

🏭 Applications & Case Scenes

-

🧵 Nonwoven & Meltblown Lines — restores perfect micro-holes in spinnerets for stable, high-quality fiber extrusion

-

⚙️ Filtration Systems — rejuvenates complex filters and screen changers to full melt-flow capacity

-

🧩 Polymer Production — ideal for PET, PP, and PA polymer cleaning and maintenance

-

🔧 High-Precision Tooling — safe cleaning of injection molds, gear pumps, and extrusion dies

📞 Request a Custom Engineering Quote

To receive your custom vacuum pyrolysis furnace design, please provide:

-

Spinneret or filter type and size

-

Polymer residue type (PET, PP, PA, ABS, etc.)

-

Required working dimensions (W × D × H)

-

Target cleaning cycle time

Contact Technical Sales

📱 WhatsApp: +86-19106101572

📧 Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Extrusion Moulds — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Melt Pipes — Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Screw Cleaning – Automated Industrial Cleaning System