Vacuum Cleaning Oven for the Plastics Industry — Fully Automatic Polymer Removal System

The Ruiyuan Vacuum Cleaning Oven is designed for automated polymer and carbon residue removal in the plastics and extrusion industry. Operating under −0.085 MPa vacuum and up to 450 °C, it provides safe, efficient cleaning of filters, dies, and mould parts. With PLC temperature control, high thermal efficiency (≥98%), and residue-free results, it helps maintain precision, reduce downtime, and improve product quality.

Get Your Customised Product

🧴 Vacuum Cleaning Oven for the Plastics Industry | Automatic Polymer Removal System

Product Overview

The Vacuum Cleaning Oven for the Plastics Industry features an electrically heated, vacuum-sealed chamber for fully automatic cleaning of plastic processing tools such as filters, dies, breaker plates, and nozzles.

Its three-phase process — Melting → Pyrolysis → Oxidation — safely removes polymer residues without damaging tooling. Precise PLC/PID temperature and vacuum control ensure high cleaning efficiency, while the energy-efficient design supports eco-friendly and reliable operation.

Key Benefits for Buyers

✅ Designed for plastics production and extrusion tools

✅ Fully automatic cleaning cycle — no manual handling required

✅ Accurate PLC/PID temperature control prevents tool deformation

✅ High thermal efficiency (≥98%) reduces energy consumption

✅ Smooth, clean surfaces restore equipment performance

✅ Safe and environmentally friendly with sealed vacuum and exhaust scrubber

Product Features

-

Heating Method: Electric heating under vacuum

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450°C

-

Temperature Control: PLC/PID system with ±1°C precision

-

Cleaning Process: Automatic — Melting → Pyrolysis → Oxidation

-

Thermal Efficiency: ≥98%

-

Structure: All-welded stainless steel vacuum chamber with collector tray

-

Safety System: Over-temperature alarm, vacuum interlock, controlled oxidation, emergency stop

-

Optional: Dual-stage water scrubber for exhaust purification and condensate collection

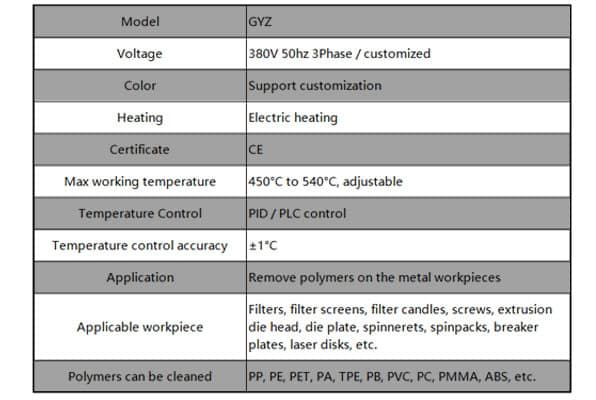

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Cleaning Oven for the Plastics Industry |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450°C |

| Temperature Control | PLC/PID precision system with ±1°C accuracy |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless steel chamber |

| Standard Voltage | 380 V / 50 Hz (customizable) |

| Typical Applications | Plastic moulds, extrusion dies, filters, breaker plates, nozzles |

| Safety & Control | Over-temperature protection, vacuum interlock, gas scrubber, alarm system |

Working Principle

I. Melting Phase

Components are heated to 320°C under vacuum, melting polymer residues that drain into the collection tray.

II. Pyrolysis Phase

Remaining polymers are vaporized and decomposed under vacuum, with exhaust gases passed through a secondary water scrubber to remove condensates.

III. Oxidation Phase

Residual carbon is oxidized under controlled air flow, leaving tooling surfaces clean, smooth, and ready for reuse.

Applications & Case Scenes

🏭 Extrusion and injection tool cleaning — restores part precision and consistency

🧩 Filter and die head maintenance — removes plastic and carbon buildup efficiently

🛠 Mould and nozzle cleaning — ensures longer service life and production stability

🔧 Maintenance workshops — safe, automatic, and easy to operate for daily cleaning

Request a Quote

Provide your tool type, polymer material, cleaning frequency, and chamber size, and our engineers will design a custom vacuum cleaning system tailored for your plastics production needs.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

PLC-Controlled Vacuum Cleaning Oven for Extrusion Tools — Fully Automatic Polymer Removal

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Cleaning Filters — Fully Automatic Polymer Removal Furnace