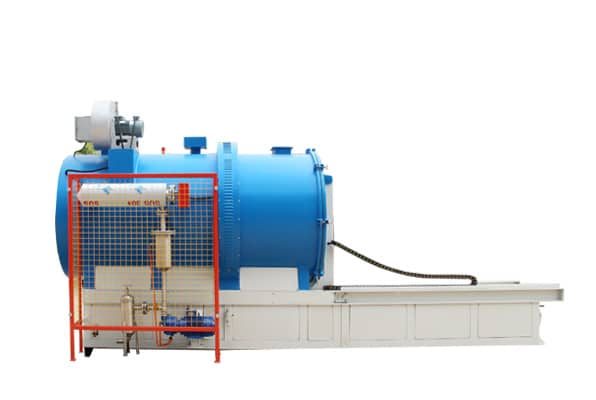

Vacuum Cleaning Oven for Extrusion Moulds — Fully Automatic Polymer Removal System

The Ruiyuan Vacuum Cleaning Oven provides safe, efficient, and automatic polymer residue removal from extrusion moulds, dies, and tooling. Operating at −0.085 MPa vacuum and up to 450 °C, it combines melting, pyrolysis, and oxidation stages to clean thoroughly without deformation. With precise PLC/PID control and ≥98 % thermal efficiency, it restores mould performance while lowering maintenance time and costs.

Get Your Customised Product

🧰 Vacuum Cleaning Oven for Extrusion Moulds | Automated Tool Cleaning

Product Overview

The Vacuum Cleaning Oven for Extrusion Moulds uses vacuum electric heating to remove plastic and polymer residues from extrusion tooling, moulds, and dies. Its automatic multi-phase cleaning process—melting, pyrolysis, and oxidation—ensures complete residue decomposition, producing smooth, residue-free surfaces.

Designed for extrusion and plastic processing plants, this oven offers energy-efficient, environmentally friendly cleaning with precise temperature control and minimal manual intervention.

Key Benefits for Buyers

✅ Dedicated cleaning solution for extrusion moulds and dies

✅ Automatic cleaning cycle eliminates manual scraping or burning

✅ High precision temperature control maintains tooling integrity

✅ Energy efficient – ≥98% thermal efficiency reduces operating costs

✅ Eco-friendly – closed vacuum design with scrubbed exhaust

✅ Clean, smooth tooling surfaces restore extrusion precision and reduce downtime

Product Features

-

Heating Method: Electric heating under vacuum conditions

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450°C

-

Temperature Control: PLC/PID regulation with ±1°C precision

-

Cleaning Cycle: Fully automatic – Melting → Pyrolysis → Oxidation

-

Thermal Efficiency: ≥98%

-

Construction: All-welded stainless steel chamber with condensate collector

-

Safety Features: Over-temperature alarm, vacuum interlock, controlled oxidation, emergency stop

-

Optional: Dual scrubber exhaust system for gas purification and condensate drainage

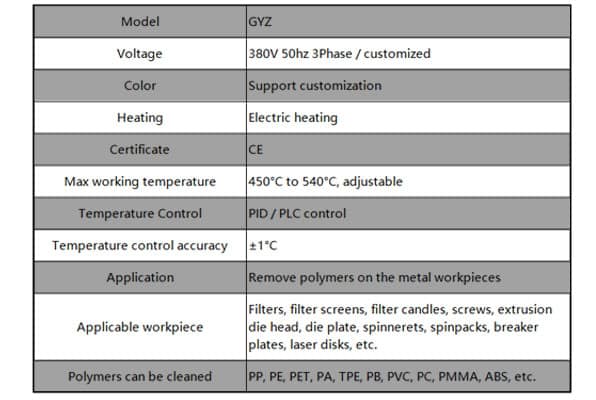

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Cleaning Oven for Extrusion Moulds |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450°C |

| Temperature Control | PLC/PID precision control with thermocouple feedback |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless-steel vacuum chamber |

| Standard Voltage | 380V / 50Hz (customizable) |

| Typical Applications | Extrusion moulds, dies, filters, nozzles, breaker plates |

| Safety & Control | Over-temperature, vacuum interlock, gas scrubber, alarm system |

Working Principle

I. Melting Phase

Moulds are gradually heated to 320°C under vacuum, melting polymer residues that drain into the collection tank.

II. Pyrolysis Phase

Remaining polymer undergoes pyrolysis under vacuum, with gases passed through a secondary water scrubber, removing condensates and ensuring clean exhaust.

III. Oxidation Phase

Residual carbon and ash are oxidized under controlled air supply, leaving a clean, residue-free surface.

Applications & Case Scenes

-

⚙️ Extrusion Mould and Die Cleaning – Removes polymers, adhesives, and carbon buildup

-

🏭 Plastic and Rubber Processing – Maintains extrusion line precision

-

🛠 Filter and Nozzle Cleaning – Restores consistent melt flow and finish quality

-

✅ Maintenance Workshops – Safe, automatic cleaning for daily tool maintenance

Request a Quote

Provide your mould dimensions, polymer type, cleaning frequency, and installation details, and Ruiyuan engineers will design a tailored vacuum cleaning solution for your extrusion operations.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for the Film Industry — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Melt Pipes — Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Screw Cleaning – Automated Industrial Cleaning System