Air Heaters for Meltblown Fabrics in Polypropylene Spunbond Nonwoven Lines

Specialized air heaters designed specifically for meltblown and spunbond nonwoven production lines processing polypropylene fabrics. These 380V heaters deliver high thermal efficiency and rapid warming for consistent fiber processing. With compact design and durable construction, they ensure reliable performance in continuous nonwoven manufacturing operations. Customizable configurations available for specific production line requirements.

Get Your Customised Product

🌬️ Air Heater for Meltblown & Spunbond Nonwoven Lines | China Ryan

Product Overview

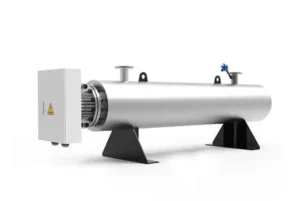

The Air Heater for Meltblown and Spunbond Nonwoven Lines is a high-precision industrial heating system designed for polypropylene fiber processing in nonwoven manufacturing. Operating at 380 V, it uses tubular electric heating elements with magnesium oxide (MgO) insulation in a compact, durable housing, ensuring efficient and consistent heat transfer.

This system is engineered for continuous operation, maintaining stable air temperatures that are critical for fiber formation, fabric quality, and high-efficiency production.

Key Benefits for Buyers

✅ Industry-Specific Design – Optimized for meltblown and spunbond nonwoven production lines.

✅ Precision Temperature Control – Ensures consistent polypropylene fiber quality.

✅ Rapid Thermal Response – Maintains production line efficiency and throughput.

✅ Energy-Efficient Operation – Reduces manufacturing energy costs.

✅ Compact Footprint – Integrates seamlessly into existing production lines.

✅ Custom Configurations – Tailored for specific nonwoven line requirements.

✅ Durable Construction – Built for continuous industrial operation.

Product Features

-

Application-Specific: Designed for meltblown and spunbond nonwoven lines

-

Input Voltage: 380 V industrial standard

-

Heating Technology: Tubular electric elements with MgO insulation

-

Thermal Efficiency: High-efficiency heat transfer

-

Heating Speed: Rapid response for production needs

-

Construction: Compact, industrial-grade materials with deflector plates

-

Customization: Non-standard designs available for specific production lines

-

Performance: Reliable operation for continuous manufacturing

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Air Heater for Meltblown/Spunbond Nonwoven Lines |

| Application | Polypropylene nonwoven fabric production |

| Input Voltage | 380 V |

| Heating Technology | Tubular electric heating elements |

| Insulation Material | Magnesium oxide powder |

| Thermal Efficiency | High efficiency rating |

| Construction | Compact design with deflector plates |

| Customization | Available for specific line requirements |

Working Principle

The heater uses tubular electric heating elements with high-temperature resistance wires sealed in metal tubes. Crystalline magnesium oxide powder fills the voids, providing excellent electrical insulation and efficient heat conduction.

Process air passes over the heated elements, absorbing the precise thermal energy required for polypropylene fiber processing. This ensures consistent air temperatures, which are crucial for high-quality fiber formation and nonwoven fabric production.

Applications & Case Scenarios

-

🧵 Meltblown Nonwoven Lines – Process air heating for fine fiber production

-

🪡 Spunbond Nonwoven Lines – Air heating for continuous filament processes

-

⚙️ Polypropylene Processing – Specialized heating for PP fiber formation

-

🏭 Nonwoven Manufacturing – Medical, filtration, and technical textile production

-

🔧 Production Line Upgrades – Retrofitting existing nonwoven equipment

-

🧪 Custom Nonwoven Applications – Specialized fabric manufacturing processes

Request a Custom Quote

Provide your production specifications, including line type (meltblown/spunbond), production capacity, temperature requirements, and space constraints. Our team will design a custom air heating solution optimized for your production needs.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com