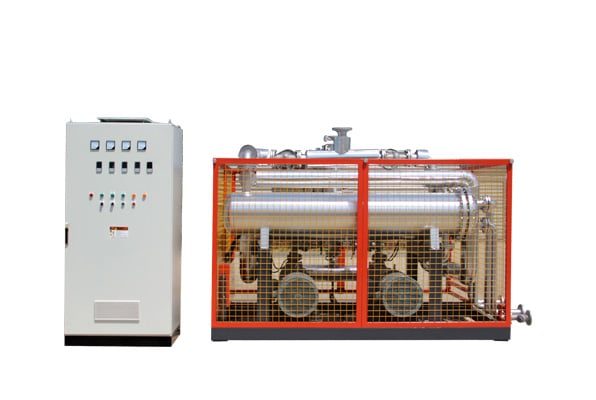

Heating & Cooling Integrated Electric Thermal Oil Boiler — 10-4200 kW Power

Ruiyan’s heating & cooling integrated electric thermal oil boiler combines high-temperature heating and cooling capabilities in one efficient system with power options from 10 kW to 4200 kW. Featuring PLC/PID control, ±1°C temperature accuracy, and ≥98% thermal efficiency, this system provides reliable thermal management for reactors, dryers, rollers, and continuous processing lines. Standard voltage 380V/50Hz with custom configurations available.

Get Your Customised Product

🌡️ Heating & Cooling Integrated Electric Thermal Oil Boiler — Dual-Function Thermal System

🧠 Product Overview

The Ruiyuan Heating & Cooling Integrated Electric Thermal Oil Boiler delivers both high-temperature heating and precision cooling within one compact modular system.

Available in power ranges from 10 kW to 4200 kW, this unit is fully customizable to meet specific industrial needs. Utilizing electric heating (flange or seamless tube elements) and an integrated cooling circuit, the system employs PLC/PID intelligent control and solid-state temperature regulation with ±1°C accuracy to ensure precise thermal stability.

With thermal efficiency ≥98%, a fully welded boiler body (stainless or carbon steel), and a space-saving design, it’s ideal for reactors, drying production lines, laminating rollers, and continuous processing systems across chemical, textile, and manufacturing industries.

⚙️ Key Benefits

✅ Integrated Heating & Cooling — Combines dual functions into one system, reducing footprint and simplifying installation.

✅ High Energy Efficiency — Delivers ≥98% thermal efficiency, minimizing energy consumption and operational costs.

✅ Precision Temperature Control — PLC/PID + solid-state SCR technology ensures ±1°C process stability.

✅ Modular Design — Compact structure with rapid commissioning and full customization support.

✅ Safety & Reliability — Closed-loop operation eliminates pressure risks and includes multiple safety interlocks.

🔍 Product Features

| Feature | Specification / Benefit |

|---|---|

| Power Range | 10–4200 kW (Customizable) |

| Heating & Cooling Method | Electric heating (flange/seamless tube elements) + integrated cooling circuit |

| Control System | PLC/PID with solid-state/SCR regulation, dual-loop logic |

| Structure Material | Fully welded body in stainless or carbon steel |

| Thermal Efficiency | ≥98% |

| Temperature Control Accuracy | ±1°C (PID precision) |

| Voltage/Frequency | 380 V / 50 Hz (Customizable) |

| Key Components | Flange heaters, centrifugal/shield pumps, sensors, insulation, oil ports, valves, control panel |

📊 Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Heating & Cooling Integrated Electric Thermal Oil Boiler |

| Power Output | 10–4200 kW (Customizable) |

| Heating/Cooling Method | Electric heating with integrated cooling circuit |

| Thermal Efficiency | ≥98% |

| Temperature Control | PLC/PID + SCR; ±1°C precision |

| Structure/Material | Fully welded body; stainless or carbon steel |

| Standard Voltage | 380 V / 50 Hz (Customizable) |

| Typical Applications | Reactors, drying lines, rollers, laminating, tunnel ovens, continuous manufacturing |

| Control & Monitoring | Omron temperature meter, remote/DCS compatibility, dual-loop logic |

🔬 Working Principle

This dual-function thermal oil system uses organic heat transfer oil as the thermal carrier. A high-temperature oil pump drives forced circulation, ensuring consistent heat delivery and uniform temperature across equipment.

The integrated cooling circuit and three-way proportional valve enable seamless switching between heating and cooling modes, making it suitable for processes requiring precise temperature transitions.

🏭 Applications & Industries

✅ Chemical Industry — Reactors, distillation columns, polymerization systems requiring controlled heating & cooling.

✅ Plastics & Rubber Industry — Ideal for extrusion, surface coating, and rubber curing.

✅ Textile Printing & Dyeing — Enables high-precision thermal control for dyeing and heat treatment processes.

✅ Food Processing — Ensures uniform heating for cooking, baking, and drying applications.

✅ Equipment Manufacturing — Stable temperature regulation for molds, bearings, and forging applications.

🌟 Key Benefits at a Glance

-

Energy-efficient dual heating & cooling design (≥98%)

-

Accurate ±1°C process temperature control

-

Fully automatic PLC/PID regulation system

-

Durable welded construction — stainless or carbon steel

-

Safe, closed-loop design for industrial-grade reliability

📞 Request a Custom Engineering Quote

To design your custom integrated heating-cooling system, please share your process details:

-

Required Temperature Range

-

Heat Load (kW)

-

Oil Type & Cooling Requirements

-

Footprint & Installation Constraints

📩 Email: sabbir@cnryan.com

📱 WhatsApp: +86-19106101572

Ruiyuan Engineering — Your Partner for Precision Thermal Control Solutions.

Related products

-

Thermal oil boiler

Industrial Electric Thermal Oil Circulation System — 10–4200 kW

-

Thermal oil boiler

Explosion-Proof Electric Heating Thermal Oil Boiler – 10-4200 kW

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Asphalt Tanks – 10-4200 kW

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Dryer (10-4200 kW)