Heating & Cooling Integrated Electrically Heated Thermal Oil Boiler — 10–4200 kW

This heating & cooling integrated electric thermal oil boiler from Ruiyuan combines high-temperature heating and cooling capability in one system with power options from 10 kW to 4200 kW. Featuring electric heating, PLC/PID control, solid-state temperature regulation, and premium all-welded construction, it offers unmatched flexibility for reactors, dryers, rollers and continuous processing lines. Thermal efficiency ≥98% and standard voltage 380 V / 50 Hz (customisable).

Get Your Customised Product

🔥 Heating & Cooling Integrated Electrically Heated Thermal Oil Boiler — 10 to 4200 kW | PLC-Controlled

Product Overview

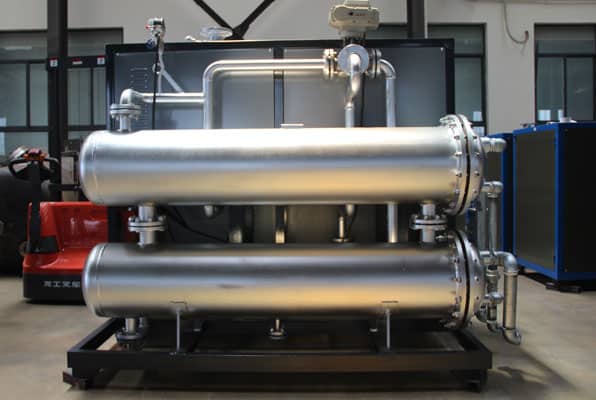

The Heating & Cooling Integrated Electrically Heated Thermal Oil Boiler utilizes a advanced heat-transfer oil circulation system driven by high-temperature pumps to deliver both heating and cooling functions within a single modular skid. Featuring integrated thermal circuits, precision PLC/PID control, and optional solid-state regulation, this system enables complex temperature profiles, rapid process cycling, and high-efficiency operation across various industrial applications.

Key Benefits for Buyers

✅ Dual-Function System — Integrated heating and cooling reduces equipment footprint and installation complexity

✅ Superior Energy Efficiency — ≥98% thermal efficiency significantly lowers operating costs

✅ Precision Temperature Control — PLC/PID with solid-state regulation maintains ±1°C accuracy

✅ Rapid Commissioning — Modular skid design enables quick installation and startup

✅ Customizable Solutions — Flexible power, materials, and configuration options available

✅ Advanced Process Control — Supports complex temperature profiles for quality manufacturing

✅ Reduced Operating Costs — High efficiency design minimizes energy waste

Product Features

Power Range: 10–4200 kW (fully customizable)

Heating Method: Electric heating with flange/seamless tube elements plus integrated cooling circuit

Control System: PLC/PID with solid-state/silicon regulation and dual-loop logic

Construction: All-welded boiler body — stainless steel or carbon steel options

Thermal Efficiency: ≥98% with advanced insulation

Temperature Accuracy: ±1°C with PID control

Standard Voltage: 380V/50Hz (custom configurations available)

Key Components: High-efficiency heaters, centrifugal pumps, precision sensors, ceramic-fiber insulation, and heating-cooling change-over valves

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Heating & Cooling Integrated Electrically Heated Thermal Oil Boiler |

| Power Output | 10–4200 kW (Customizable) |

| Heating/Cooling Method | Electric Heating with Integrated Cooling Loop |

| Thermal Efficiency | ≥98% |

| Temperature Control | PLC/PID ±1°C Accuracy |

| Control Method | Solid-State/Silicon Controlled |

| Construction | All-Welded Body Structure |

| Materials | Stainless Steel / Carbon Steel |

| Standard Voltage | 380V/50Hz (Customizable) |

| Monitoring | Omron Temperature Meters, Remote/DCS Support |

| Applications | Reactors, Dryer Lines, Laminating Systems, Tunnel Ovens |

Working Principle

The system operates through a closed-loop thermal oil circuit where electric heaters raise temperature during heating phases, while integrated cooling circuits facilitate controlled cooldown. The PLC-controlled system manages transition between heating and cooling modes, maintaining precise temperature profiles through solid-state power regulation and advanced PID algorithms.

Applications & Industries

🏭 Chemical Processing — Reactors requiring precise heating and cooling cycles

🛠 Plastic & Rubber Manufacturing — Mold temperature control and process cooling

💡 Building Materials — Laminating lines and coating systems with thermal management

🔧 Food Processing — Cooking and cooling processes in production lines

🏗 Textile Industry — Dryer lines with rapid cooling requirements

🔬 Advanced Manufacturing — New materials production requiring flexible thermal profiles

Request Custom Solution

Provide your specific process requirements including temperature range, thermal capacity (kW), oil type, cooling needs, and installation constraints. Our engineering team will design a tailored heating-cooling system optimized for your production line.

📞 Contact Our Thermal Engineering Team

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

🎯 Need integrated heating and cooling for your industrial process? Contact us today for a free technical consultation and customized solution proposal!