Industrial Electric Thermal Oil Circulation System — 10–4200 kW

This industrial electric thermal oil circulation system (heat-transfer oil heater) from Ruiyuan provides stable, high-efficiency process heat for reactors, dryers, rollers and asphalt tanks. Available in custom outputs from 10 to 4200 kW, the system uses electric heating, PLC/PID control, solid-state temperature regulation and all-welded construction. Thermal efficiency ≥98% and standard 380 V / 50 Hz (customisation available).

Get Your Customised Product

🔥 Industrial Electric Thermal Oil Circulation System — 10 to 4200 kW | PLC-Controlled

Product Overview

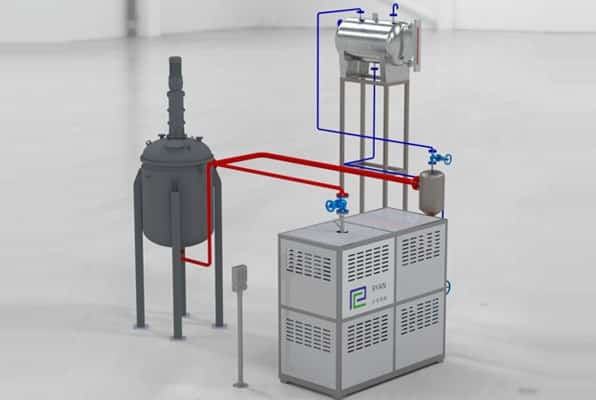

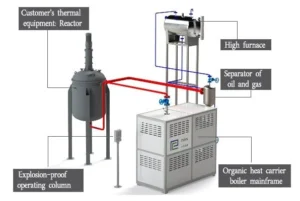

The Industrial Electric Thermal Oil Circulation System delivers continuous, uniform thermal energy to industrial equipment through advanced forced circulation technology. Utilizing organic heat-transfer oil and high-temperature pumps, this system ensures precise thermal distribution to multiple heat users simultaneously. Featuring flange-mounted electric heaters for easy maintenance, comprehensive PLC/PID control, and robust safety systems, this solution provides reliable heating performance for demanding industrial processes while supporting seamless integration into existing production lines.

Key Benefits for Buyers

✅ Continuous Thermal Supply — Reliable heating for reactors, dryers, and industrial rollers

✅ Maximum Energy Efficiency — ≥98% thermal efficiency reduces operating costs

✅ Precision Temperature Control — PLC/PID with solid-state regulation maintains ±1°C accuracy

✅ Easy Maintenance Access — Flange-mounted heaters enable quick replacement and service

✅ Flexible Configuration — Customizable power, dimensions, and materials for unique spaces

✅ Rapid Installation — Modular skid design simplifies on-site setup and piping connections

✅ Multi-User Support — Forced circulation ensures consistent heat distribution to all points

Product Features

Power Range: 10–4200 kW (fully customizable)

Heating Method: Electric heating with flange/special seamless tube heaters

Control System: PLC/PID with solid-state/silicon regulation

Construction: All-welded boiler body — stainless steel or carbon steel options

Thermal Efficiency: ≥98% with advanced ceramic-fiber insulation

Temperature Accuracy: ±1°C with precision PID control

Standard Voltage: 380V/50Hz (custom configurations available)

Key Components: Stainless steel flange heaters, centrifugal/shield pumps, thermistor sensors, explosion-proof gauges, and comprehensive control system

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Industrial Electric Thermal Oil Circulation System |

| Power Output | 10–4200 kW (Customizable) |

| Heating Method | Electric Heating (Flange/Seamless Tube Heaters) |

| Thermal Efficiency | ≥98% |

| Temperature Control | PLC/PID ±1°C Accuracy |

| Control Method | Solid-State/Silicon Controlled |

| Construction | All-Welded Body Structure |

| Materials | Stainless Steel / Carbon Steel |

| Standard Voltage | 380V/50Hz (Customizable) |

| Monitoring | Omron Temperature Meters, Remote/DCS Support |

| Safety Features | Explosion-Proof Gauges and Optional Motors |

Working Principle

The system operates through forced circulation of thermal oil, where electric heating elements transfer energy to the oil before high-temperature pumps distribute it to various process points. The PLC-controlled system continuously monitors and adjusts temperature at each stage, while solid-state regulation ensures precise thermal management throughout the entire circulation loop.

Applications & Industries

🏭 Hydraulic Press Systems — Precise temperature control for material forming processes

🛠 Laminating Production Lines — Accurate multi-zone heating for consistent quality

💡 Tunnel Oven Operations — Efficient heat transfer for extended continuous ovens

🔧 Pharmaceutical Manufacturing — Clean, stable thermal supply for sensitive production

🏗 Chemical Processing — Reliable heating for reactors and mixing vessels

🔬 Building Materials — Consistent thermal energy for composite material production

Request Custom Solution

Share your specific heating requirements including temperature ranges, thermal capacity needs, oil type preferences, spatial limitations, and installation parameters. Our engineering team will design a tailored circulation system optimized for your industrial process requirements.

📞 Contact Our Thermal Engineering Team

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

🎯 Need reliable industrial heating circulation? Contact us today for a free technical consultation and customized system proposal!

Related products

-

Thermal oil boiler

Triethylene Glycol (TEG) Cleaning Furnace – Ruiyuan Industrial Equipment

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Dryers – 10-4200 kW