Skid-Mounted Heating & Cooling Integrated Electric Thermal Oil Furnace — 10 to 4200 kW

Organic heat carrier (heat transfer oil) as a heat transfer medium, through the high temperature oil pump will heat transfer oil in the system for mandatory circulation, so that it is heated week after week, so as to achieve the purpose of meeting the heat user (heat equipment or heat cycle) to obtain the required thermal energy continuously.

Get Your Customised Product

🔥 Skid-Mounted Heating & Cooling Integrated Electric Thermal Oil Furnace — 10 to 4200 kW | PLC-Controlled

Product Overview

Our Skid-Mounted Heating & Cooling Integrated Electric Thermal Oil Furnace delivers precise temperature control for industrial processes through advanced electric heating and integrated cooling systems. Built with all-welded construction and PLC/PID control technology, this thermal oil boiler maintains exceptional temperature accuracy (±1°C) while achieving over 98% thermal efficiency. The complete skid-mounted design ensures easy installation and optimal performance for various industrial heating applications.

Key Benefits for Buyers

✅ Complete Skid-Mounted Solution — Pre-assembled for quick installation and reduced setup time

✅ Precision Temperature Control — PLC/PID system maintains ±1°C accuracy for process stability

✅ Exceptional Energy Efficiency — ≥98% thermal efficiency reduces operating costs significantly

✅ Flexible Power Range — Available from 10 kW to 4200 kW to match your specific requirements

✅ Integrated Heating & Cooling — Single system handles both heating and cooling processes

✅ Robust Construction — All-welded structure ensures long-term reliability and safety

✅ Customizable Design — Non-standard configurations available for unique application needs

Product Features

Heating Method: Electric heating elements for consistent thermal performance

Control System: Advanced PLC/PID with solid-state/SCR power regulation

Temperature Accuracy: ±1°C for precise process control

Thermal Efficiency: ≥98% with optimized heat transfer design

Construction: All-welded structure (stainless steel/carbon steel options)

Cooling Integration: Built-in cooling system for complete temperature management

Safety Features: Multiple protection systems including over-temperature and pressure safety

Installation: Pre-fabricated skid design for minimal site preparation

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Skid-Mounted Heating & Cooling Integrated Electric Thermal Oil Furnace |

| Heating Power | 10-4200 kW (Customizable) |

| Heating Capacity | 0.83-350×10000 kcal/h |

| Thermal Efficiency | ≥98% |

| Temperature Control | PLC/PID Regulation (±1°C Accuracy) |

| Control Method | Solid State/Silicon Controlled |

| Heater Oil Capacity | 15-2100L (Model Dependent) |

| Pump Power | 1.5-37 kW (Model Dependent) |

| Flow Rate | 6-100 M³/H |

| Pump Head | 28-80m |

| Construction | All-Welded Structure |

| Materials | Stainless Steel / Carbon Steel |

| Standard Models | GYD-10 to GYD-1400+ |

Working Principle

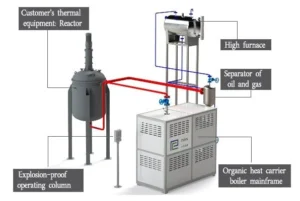

The thermal oil furnace operates through electric heating elements that transfer heat to the thermal oil circulating within a closed-loop system. The PLC-controlled system precisely regulates temperature through solid-state power controllers, while integrated cooling capabilities allow for both heating and cooling cycles. The skid-mounted design incorporates all necessary components including expansion tanks, circulation pumps, and control systems for complete operational readiness.

Applications & Industries

🏭 Chemical Processing — Precise temperature control for reactors and distillation systems

🛠 Plastic & Rubber Manufacturing — Mold heating and extruder temperature maintenance

💡 Oil & Gas Processing — Viscosity control and process heating applications

🔧 Food Processing — Cooking oil heating and food production line temperature control

🏗 Textile Industry — Heat setting and drying process temperature management

🔬 Pharmaceutical Manufacturing — Reactor temperature control and process heating

Request Custom Solution

Share your specific heating requirements including temperature range, thermal power needs, process application, and space constraints. Our engineers will design a tailored thermal oil furnace system that matches your exact industrial process requirements.

📞 Contact Our Thermal Solutions Team

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

🎯 Need precise temperature control for your industrial process? Message us now for a free technical consultation and customized thermal solution!

Related products

-

Thermal oil boiler

Cooling Temperature Control Unit

-

Thermal oil boiler

Triethylene Glycol (TEG) Cleaning Furnace – Ruiyuan Industrial Equipment

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Dryer (10-4200 kW)

-

Thermal oil boiler

Electric Thermal Oil Boiler Heater for Heating Dryers – 10-4200 kW