🧼 Ruiyuan TEG Cleaning Furnace | Automated Solvent-Free Polymer Cleaning System | PLC-Controlled

Product Overview

The Ruiyuan TEG Cleaning Furnace delivers advanced cleaning performance for polymer-contaminated industrial components using heated triethylene glycol (TEG) technology. Specifically engineered for spinnerets, filters, screen packs, and precision molds, this system eliminates tough polymer residues through elevated temperature cleaning (180-300°C) without harsh chemicals. With fully automated PLC control, customizable chamber sizes, and efficient TEG circulation, this furnace ensures thorough cleaning while reducing cycle times and operational costs.

Key Benefits for Buyers

✅ Deep Polymer Removal — Effectively dissolves and removes high-adhesion residues from critical components

✅ Solvent-Free Cleaning — TEG medium provides environmentally safer alternative to chemical solvents

✅ Precision Temperature Control — PLC/PID system maintains ±1°C accuracy for consistent results

✅ Customizable Chamber Sizes — Available from 50L to 3000L+ to match your production batch needs

✅ Reduced Operating Costs — Low energy consumption and minimal manual intervention

✅ Enhanced Safety Features — Over-heat protection, leakage detection, and automated operation

✅ Faster Cycle Times — Typical cleaning cycles from 30 minutes to 3 hours depending on contamination

Product Features

Cleaning Method: Heated TEG bath circulation system

Temperature Range: 180°C–300°C (custom models up to 350°C)

Control System: Automated PLC/PID with precise temperature regulation

Construction: Stainless steel tank with insulation jacket

Volume Options: Small (50-200L), Medium (500-2000L), Large (3000L+)

Monitoring: Intelligent control with parameter settings, alarms, and remote monitoring options

Filtration: Integrated impurity filtration for extended TEG life

Safety Systems: Comprehensive protection including over-temperature and leakage detection

Technical Specification

| Parameter | Specification |

|---|---|

| Product Name | Ruiyuan TEG Cleaning Furnace |

| Chamber Volume | 50L–3000L+ (Customizable) |

| Heating Method | Electric TEG Bath Heating |

| Operating Temperature | 180°C–300°C (Up to 350°C Custom) |

| Temperature Control | PLC/PID ±1°C Accuracy |

| Cleaning Cycle | 30 minutes to 3 hours (Contamination Dependent) |

| Construction | Stainless Steel Tank & Jacket |

| Control System | PLC Intelligent Control with Remote Monitoring |

| Applications | Spinnerets, Filters, Molds, Screen Packs |

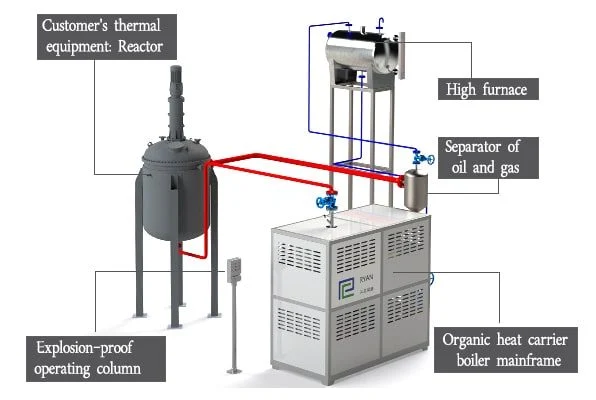

Working Principle

The system operates by heating triethylene glycol to optimal cleaning temperatures (180-300°C) where it effectively dissolves and removes polymer residues from industrial components. The TEG circulates throughout the chamber, ensuring complete coverage and penetration of complex geometries. The PLC-controlled system maintains precise temperature profiles while monitoring all safety parameters, delivering consistent cleaning performance with minimal operator intervention.

Applications & Industries

🏭 Nonwoven Manufacturing — Spinneret and filter cleaning for melt-blown and spun-bond production

🛠 Textile Fiber Production — Precision cleaning of fiber extrusion components

💡 Plastic & Rubber Industry — Mold and extrusion die maintenance

🔧 Chemical Processing — Industrial filter and mesh cleaning

🏗 Pharmaceutical Manufacturing — Equipment cleaning where polymer fouling occurs

🔬 Electronics Industry — Precision component maintenance

Why Choose Ruiyuan

With manufacturing expertise since 2008, 23,000 m² production facility, and over 160 industry certifications, Ruiyuan delivers reliable, factory-direct cleaning solutions. Our engineering team provides custom-designed TEG cleaning systems with fast turnaround and global export support, ensuring minimal downtime for your production operations.

Request Custom Solution

Share your component specifications, polymer types, production volume, and cleaning cycle requirements. Our engineering team will design a tailored TEG cleaning system optimized for your specific application needs.

📞 Contact Our Cleaning Solutions Team

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

🎯 Ready to upgrade your cleaning process? Contact us today for a free technical consultation and customized TEG furnace proposal!

Related products

-

Thermal oil boiler

Electric Heating Thermal Oil Boiler — 10–4200 kW