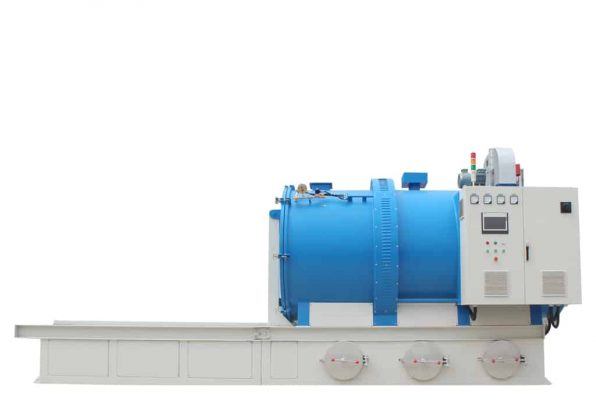

Vacuum Cleaning Furnace for Cleaning Melt Pipes — Automatic Polymer Removal System

The Ruiyuan Vacuum Cleaning Furnace for Cleaning Melt Pipes ensures complete and safe removal of polymer and carbon residues from melt pipes, filters, and extrusion parts. Featuring −0.085 MPa vacuum, 450 °C electric heating, and a fully automated PLC-controlled process, it delivers clean, smooth surfaces with minimal energy consumption. Ideal for high-precision applications in plastics, chemical fiber, and nonwoven industries.

Get Your Customised Product

🔹 Vacuum Cleaning Furnace for Melt Pipes | PLC-Controlled

Product Overview

The Vacuum Cleaning Furnace for Cleaning Melt Pipes uses an electrically heated vacuum chamber to safely and efficiently remove polymer residues from melt pipes and other precision components. Its fully automated multi-phase cleaning cycle (melting → pyrolysis → oxidation) ensures residue-free results without deformation or mechanical damage. Designed for continuous or batch cleaning, it offers a reliable, energy-efficient, and environmentally friendly solution for polymer and fiber manufacturing facilities.

Key Benefits for Buyers

✅ Fully automated process — PLC-controlled melting, pyrolysis, and oxidation

✅ High cleaning efficiency — removes all polymer residues with minimal supervision

✅ Accurate temperature control — prevents distortion of melt pipes

✅ Energy-saving design — ≥98% thermal efficiency with low power consumption

✅ Safe vacuum operation — emission-free and eco-friendly

✅ Compact structure — suitable for production lines and maintenance workshops

Product Features

-

Heating Method: Electric heating under vacuum

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450 °C

-

Temperature Control: PLC/PID precision with thermocouple feedback

-

Cleaning Phases: Melting → Pyrolysis → Oxidation (automatic sequence)

-

Thermal Efficiency: ≥98% with advanced insulation and minimal heat loss

-

Chamber Design: All-welded stainless-steel vacuum chamber with bottom polymer collector

-

Safety System: Over-temperature protection, vacuum interlock, automatic air purge, emergency shutdown

-

Optional: Dual-stage water scrubber for exhaust purification and condensate collection

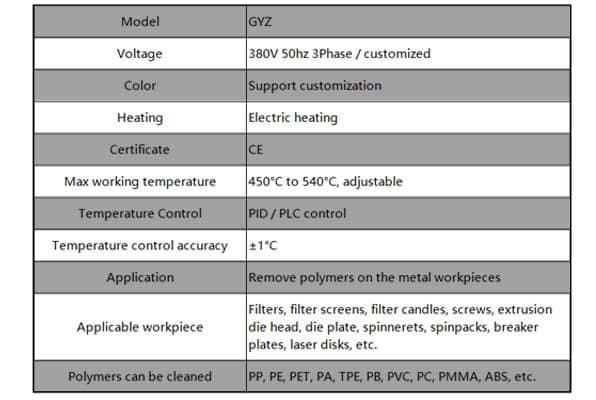

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Cleaning Furnace for Cleaning Melt Pipes |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450 °C |

| Temperature Control | PLC/PID with thermocouple monitoring |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless steel chamber |

| Standard Voltage | 380 V / 50 Hz (customisable) |

| Typical Applications | Melt pipe cleaning, filter cleaning, extrusion parts, polymer moulds |

| Safety Features | Over-temperature alarm, vacuum interlock, exhaust scrubber |

Working Principle

I. Melting Phase

Melt pipes are gently heated to 320 °C, causing polymer residues to melt and drain into the collection tray.

II. Pyrolysis Phase

Remaining residues are decomposed under vacuum, with gases scrubbed in a water-based filtration system for clean and safe exhaust.

III. Oxidation Phase

Residual carbon is oxidized under controlled air flow, leaving the melt pipe completely clean and free of polymer traces.

Applications & Case Scenes

🏭 Melt pipe cleaning — removes polymer buildup to restore optimal material flow

🛠 Filter and extrusion part maintenance — thorough cleaning for precision components

💡 Plastic and nonwoven production — prolongs the lifespan of process equipment

🔧 Maintenance workshops — automated cleaning with minimal manpower and energy

Request a Quote

Provide your melt pipe dimensions, contamination type, cleaning frequency, and workspace layout, and our engineers will design a custom vacuum furnace solution to meet your production needs.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for the Plastics Industry — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Mould Heads — Automatic Polymer Removal Furnace

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Die Head Cleaning – Automated Industrial Cleaning System