Vacuum Cleaning Furnace for Screw Cleaning – Automated Industrial Cleaning System

This vacuum cleaning furnace provides automated cleaning for screws and industrial components with polymer residues. Featuring a three-phase cleaning process (melting, pyrolysis, oxidation) and -0.085 MPa ultimate vacuum, it ensures thorough contamination removal. With electric heating, precise temperature control up to 450°C, and high thermal efficiency, it delivers clean, smooth screw threads with minimal operator intervention and low energy consumption.

Get Your Customised Product

🔥 Vacuum Cleaning Oven for Screw Cleaning – Automated Industrial Cleaning System

🧠 Product Overview

The Ruiyuan Vacuum Cleaning Oven is purpose-built for cleaning die heads, extrusion screws, and precision components contaminated with polymer residues. Utilizing a fully automated three-stage process — Melting → Pyrolysis → Oxidation — it ensures complete polymer removal without mechanical damage or oxidation.

This high-efficiency system combines PLC/PID intelligent control, deep vacuum environment, and electric heating to deliver consistent, residue-free results for extrusion, molding, and polymer processing industries. Ideal for die head and screw cleaning, it guarantees smooth, contamination-free surfaces, extends component lifespan, and enhances production quality.

⚙️ Key Benefits for Buyers

✅ Superior Cleaning Efficiency — Ensures full removal of polymer, carbon, and residue from die heads and screws.

✅ Precision Temperature Control — Maintains consistent heat for safe, stress-free cleaning.

✅ Eco-Friendly & Safe — Features a closed vacuum system with optional dual-stage water scrubber for clean exhaust.

✅ Fully Automated Operation — Reduces manual labor through PLC-controlled, hands-free cleaning cycles.

✅ Energy-Efficient Design — High thermal efficiency (≥ 98%) reduces power consumption and operational cost.

✅ Customizable Chamber Sizes — Available in multiple configurations to match your cleaning requirements.

🔍 Product Features (Technical & Safety Highlights)

| Feature | Specification / Benefit |

|---|---|

| Primary Use | Die Head, Extrusion Screw, Filter, and Mould Cleaning |

| Cleaning Method | Vacuum Pyrolysis (Controlled Polymer Decomposition) |

| Ultimate Vacuum | −0.085 MPa (Deep vacuum for low-temp cleaning) |

| Maximum Temperature | 450 °C (Safe polymer decomposition zone) |

| Control System | PLC/PID Control with Real-Time Feedback |

| Cleaning Cycle | Fully Automatic: Melting → Pyrolysis → Oxidation |

| Construction | Stainless Steel, All-Welded Vacuum Chamber |

| Safety System | Over-Temperature Alarm, Vacuum Interlock, Air Purge, Auto Shutdown |

| Optional Accessory | Dual Water Scrubber for Clean Gas Exhaust |

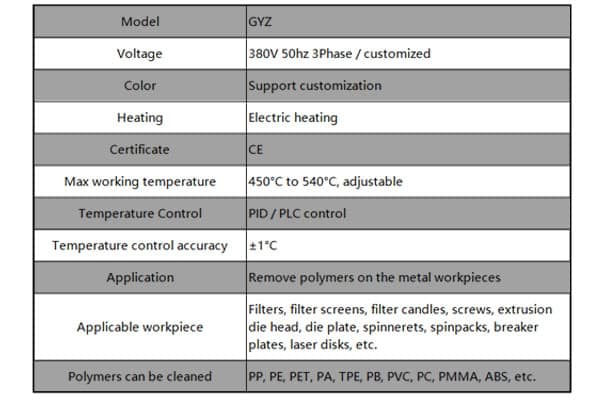

📊 Technical Specifications (Optimized for B2B SEO)

| Parameter | Specification | SEO Keywords Targeted |

|---|---|---|

| Product Name | Vacuum Cleaning Oven for Die Head Cleaning | automated industrial cleaning oven |

| Ultimate Vacuum | −0.085 MPa | vacuum pyrolysis furnace |

| Heating Method | Electric Heating | energy-efficient polymer cleaning system |

| Temperature Range | Ambient to 450 °C | controlled temperature cleaning |

| Thermal Efficiency | ≥ 98% | high-efficiency vacuum cleaning |

| Structure / Material | Stainless Steel Vacuum Chamber | corrosion-resistant furnace |

| Standard Voltage | 380 V / 50 Hz (Customizable) | industrial oven for die head cleaning |

| Typical Applications | Extrusion Dies, Mould Heads, Screws, Filters | polymer residue cleaning system |

🔬 Working Principle: Three-Phase Cleaning Process

I. Melting Phase (Bulk Removal)

Die heads and screws are gradually heated under vacuum to 320°C, melting polymer residues that flow into the collector tank.

II. Pyrolysis Phase (Deep Cleaning)

Remaining residues undergo vacuum pyrolysis, converting polymers into gas without overheating metal surfaces. Exhaust gases are scrubbed through the optional water system for clean emission.

III. Oxidation Phase (Surface Renewal)

A controlled airflow oxidizes the final carbon residues, leaving a completely clean and smooth surface, ready for reuse.

🏭 Applications & Case Scenes

✅ Extrusion Die Head Cleaning — Perfect for removing polymer buildup without deformation.

✅ Injection & Blow Molding Components — Ensures smooth flow and extended equipment life.

✅ Filter & Screw Cleaning — Ideal for restoring filtration precision and thread quality.

✅ Polymer & Fiber Production Lines — Delivers reliable cleaning for PET, PP, and PA processes.

📞 Request a Custom Engineering Quote

Upgrade your maintenance process with Ruiyuan’s Vacuum Cleaning Oven — built for precision, efficiency, and durability.

Please provide the following details for a customized quotation:

-

Die Head or Screw Dimensions (Diameter × Length)

-

Polymer Type (e.g., PET, Nylon, PP)

-

Required Cleaning Capacity

-

Installation Environment and Voltage

📩 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Extrusion Moulds — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Cleaning Filters — Fully Automatic Polymer Removal Furnace