Vacuum Cleaning Furnace for the Film Industry — Fully Automatic Polymer Removal System

The Ruiyuan Vacuum Cleaning Furnace provides automated, energy-efficient polymer removal for film extrusion and coating production lines. Operating at −0.085 MPa vacuum and 450 °C, it removes polymer and carbon residues from dies, filters, and rollers without surface damage. Featuring precise PLC temperature control and ≥98 % thermal efficiency, it guarantees clean, smooth tooling surfaces and consistent film quality.

Get Your Customised Product

🎬 Vacuum Cleaning Furnace for the Film Industry | Automated Polymer Removal System

Product Overview

The Vacuum Cleaning Furnace for the Film Industry utilizes vacuum pyrolysis and oxidation technology to completely remove polymer buildup from die heads, rollers, and filters used in film extrusion and coating lines.

By precisely controlling temperature (up to 450°C) and vacuum levels (−0.085 MPa), it ensures safe, residue-free cleaning without damaging parts. The fully automated cleaning cycle minimizes manual labor, reduces downtime, and extends equipment lifespan — essential for maintaining consistent film thickness, clarity, and quality.

Key Benefits for Buyers

✅ Purpose-built for film extrusion and coating applications

✅ Fully automatic cleaning cycle – minimal operator supervision required

✅ High-temperature electric heating (up to 450°C) ensures complete polymer removal

✅ Accurate PLC/PID temperature control for safe, repeatable performance

✅ High energy efficiency (≥98%) lowers operating costs

✅ Residue-free cleaning enhances tooling precision and film quality

Product Features

-

Heating Method: Electric heating under vacuum

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450°C

-

Temperature Control: PLC/PID system with ±1°C precision

-

Cleaning Phases: Fully automatic – Melting → Pyrolysis → Oxidation

-

Thermal Efficiency: ≥98%

-

Structure: All-welded stainless steel vacuum chamber with condensate collector

-

Safety System: Over-temperature alarm, vacuum interlock, limited-air oxidation, emergency stop

-

Optional: Dual-stage water scrubber for exhaust purification and condensate recovery

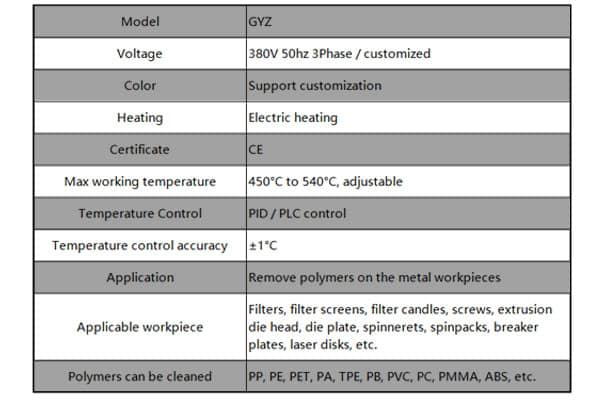

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Cleaning Furnace for the Film Industry |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450°C |

| Temperature Control | PLC/PID with ±1°C precision |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless-steel chamber |

| Standard Voltage | 380V / 50Hz (customizable) |

| Typical Applications | Film extrusion dies, coating rollers, filters, breaker plates |

| Safety & Monitoring | Over-temperature, vacuum interlock, scrubber, alarm protection |

Working Principle

I. Melting Phase

Components are slowly heated to 320°C, melting polymer residues that flow into the collection base.

II. Pyrolysis Phase

Remaining polymers undergo thermal decomposition under vacuum, with generated gases processed through a water-based scrubber for clean exhaust and condensate removal.

III. Oxidation Phase

Residual carbon and ash are oxidized under limited air supply, leaving the parts bright, clean, and ready for production reuse.

Applications & Case Scenes

🎞 Film extrusion line maintenance – Removes polymer buildup from dies and filters

🧼 Coating roller cleaning – Restores surface smoothness and uniform film thickness

🏭 Blown film & cast film production – Ensures stable melt flow and optical clarity

🔧 Workshop and lab maintenance – Automated, repeatable cleaning for precision tooling

Request a Quote

Provide your component type, polymer residue, part dimensions, and cleaning frequency, and Ruiyuan engineers will design a tailored vacuum cleaning system for your film-production equipment.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

PLC-Controlled Vacuum Cleaning Oven for Extrusion Tools — Fully Automatic Polymer Removal

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Screws — Automatic Polymer Removal Oven

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Screw Cleaning – Automated Industrial Cleaning System