Vacuum Cleaning Oven for Cleaning Filters — Fully Automatic Polymer Removal Furnace

The Ruiyuan Vacuum Cleaning Oven provides safe, precise, and automated cleaning for industrial filters, moulds, and extrusion parts. Operating under −0.085 MPa vacuum and up to 450 °C, it melts and decomposes polymer residues efficiently using electric heating. With PLC temperature control and high energy efficiency, it guarantees smooth, residue-free surfaces and easy maintenance for a wide range of applications.

Get Your Customised Product

🧴 Vacuum Pyrolysis Cleaning Oven for Die Heads & Breaker Plates | PLC-Controlled

Product Overview

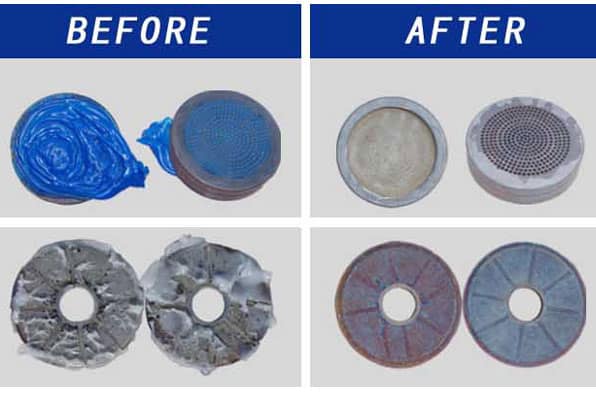

The Vacuum Pyrolysis Cleaning Oven safely removes polymer residues from die heads and breaker plates using an electrically heated vacuum chamber. Its fully automated three-phase cleaning process (melting → pyrolysis → oxidation) ensures complete decomposition of polymers without mechanical damage. Designed for plastic, nonwoven, and chemical fiber industries, it delivers smooth, residue-free surfaces while maintaining component integrity and operational efficiency.

Key Benefits for Buyers

✅ Fully automatic operation — PLC-controlled melting, pyrolysis, and oxidation

✅ Precise temperature control — prevents overheating and metal deformation

✅ High thermal efficiency (≥98%) — minimizes energy consumption

✅ Smooth, clean surfaces — improves extrusion quality and consistency

✅ Safe and eco-friendly — vacuum chamber with gas scrubber ensures clean exhaust

✅ Compact design — fits production and maintenance environments

Product Features

-

Heating Method: Electric heating under vacuum

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450 °C

-

Control System: PLC/PID with thermocouple feedback for precise regulation and automatic sequencing

-

Cleaning Phases: Melting → Pyrolysis → Oxidation (fully automated)

-

Thermal Efficiency: ≥98% with optimized insulation

-

Chamber Design: Stainless steel, fully welded, vacuum-tight

-

Safety System: Over-temperature alarm, vacuum interlock, air purge, emergency stop

-

Optional: Dual water scrubber and condensate recovery system

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Pyrolysis Cleaning Oven for Cleaning Die Heads / Breaker Plates |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450 °C |

| Temperature Control | PLC/PID with thermocouple feedback |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless-steel vacuum chamber |

| Standard Voltage | 380 V / 50 Hz (customisable) |

| Typical Applications | Die head and breaker plate cleaning, extrusion and filtration systems |

| Safety & Monitoring | Over-temperature protection, vacuum lock, gas scrubber, alarm system |

Working Principle

I. Melting Phase

Die heads and breaker plates are heated to 320 °C under vacuum, melting polymer residues which drain into the collection tank.

II. Pyrolysis Phase

Remaining polymers are pyrolyzed under vacuum, converting residues into gases. Exhaust gases pass through a secondary water scrubber for safe, clean discharge.

III. Oxidation Phase

Residual carbon is oxidized under controlled air flow, leaving clean, smooth surfaces suitable for reuse.

Applications & Case Scenes

🏭 Die head and breaker plate cleaning — removes polymer buildup for stable extrusion

🛠 Filter and mold maintenance — restores precision without abrasive tools

💡 Plastics and chemical fiber lines — ensures high-quality melt flow and output

🔧 Maintenance workshops — automated, safe, repeatable cleaning

Request a Quote

Provide your die head or breaker plate specifications (dimensions, polymer type, cleaning cycle time, and site layout), and our engineers will design a customized vacuum pyrolysis furnace solution.

📞 Contact Technical Sales

WhatsApp: +86-19106101572

Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Extrusion Moulds — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for the Film Industry — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Screws — Automatic Polymer Removal Oven