Vacuum Pyrolysis Cleaning Furnace for Cleaning Filter Elements — Automatic Polymer Removal System

The Ruiyuan Vacuum Pyrolysis Cleaning Furnace provides efficient, automatic cleaning of filter elements, moulds, and extrusion components. Using electric heating, −0.085 MPa vacuum, and a controlled pyrolysis and oxidation process up to 450 °C, it removes all polymer and carbon residues safely and completely. The system ensures smooth, residue-free surfaces while maintaining high thermal efficiency and low operating costs.

Get Your Customised Product

🔹 High-Precision Vacuum Pyrolysis Cleaning Furnace for Industrial Filter Elements | Zero-Stress Polymer Removal

🧭 Product Overview

The High-Precision Vacuum Pyrolysis Cleaning Furnace is a next-generation system designed for industrial filter element restoration, extrusion die cleaning, and polymer residue removal from precision metal tooling.

Powered by electric heating and deep vacuum technology, it performs a fully automatic three-phase cycle (Melting → Pyrolysis → Controlled Oxidation) to achieve complete, damage-free cleaning.

With PLC/PID intelligent control, the system maintains tight temperature accuracy (±1 °C), ensuring uniform, repeatable, and safe cleaning across all cycles. This makes it ideal for the plastics, chemical fiber, and filtration industries that demand precision, consistency, and extended component life.

💡 Key Benefits for Buyers

-

✅ Maximized Filter Lifespan — Gentle, stress-free cleaning prevents mesh deformation and prolongs filter life

-

✅ Guaranteed Flow Restoration — Removes micron-level polymer and carbon residues, restoring 100% filtration performance

-

✅ Low Operating Cost — ≥98% thermal efficiency significantly reduces per-cycle energy consumption

-

✅ Process Repeatability — ±1 °C temperature control ensures consistent cleaning for every batch

-

✅ Eco-Friendly Operation — Integrated vacuum with optional dual water scrubber for odorless, emission-free exhaust

-

✅ Fully Automated & Safe — PLC-controlled operation with over-temperature, vacuum interlock, and emergency purge features

⚙️ Product Features

| Feature | Specification / Benefit |

|---|---|

| Cleaning Target | Industrial filter elements, extrusion dies, melt filters, complex molds |

| Operating Method | Vacuum pyrolysis — ideal for precision and sensitive metal geometries |

| Ultimate Vacuum | −0.085 MPa (enables low-temperature polymer vaporization) |

| Maximum Temperature | 450 °C (optimized for safe polymer decomposition) |

| Control System | PLC/PID multi-phase logic with real-time thermocouple feedback |

| Thermal Efficiency | ≥98% via advanced ceramic fiber insulation |

| Chamber Integrity | All-welded stainless steel — vacuum-rated, corrosion-resistant |

| Safety Features | Over-temperature protection, vacuum interlock, automatic air purge |

| Custom Option | Dual water scrubber system for advanced emission control |

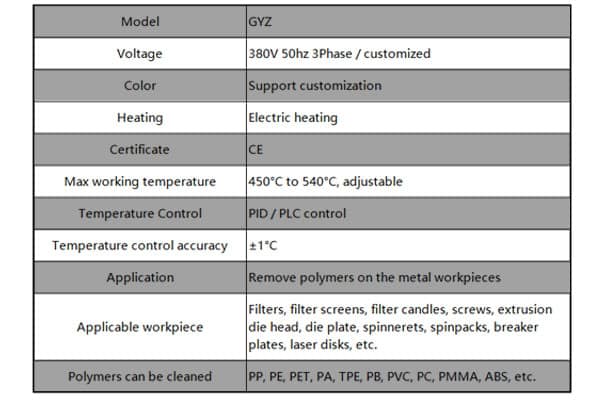

📊 Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Industrial Vacuum Pyrolysis Furnace for Filter Cleaning |

| Cleaning Phases | Melting → Pyrolysis → Controlled Oxidation |

| Temperature Control | PLC/PID regulation, ±1 °C accuracy |

| Ultimate Vacuum | −0.085 MPa |

| Power Efficiency | ≥98% thermal efficiency |

| Structure / Material | All-welded stainless-steel vacuum chamber |

| Standard Voltage | 380 V / 50 Hz (customizable) |

| Typical Applications | Filter cartridges, spinnerets, screen changers, extrusion dies |

| Safety & Monitoring | Multi-point protection, vacuum lock, alarm system, gas scrubber |

🔬 Working Principle

I. Melting Phase (Safe Drainage)

Filters are gently heated to 320 °C under vacuum, melting polymer residues that drain into a collection tray.

II. Pyrolysis Phase (Vaporization)

Remaining polymer residues are decomposed and vaporized at −0.085 MPa. Exhaust gases are drawn through a water scrubber, ensuring clean and safe discharge.

III. Controlled Oxidation Phase (Final Polish)

A controlled flow of air oxidizes remaining carbon residues, producing a bright, residue-free surface ready for immediate reuse.

🏭 Applications & Case Scenes

-

🧩 Polymer Filtration Systems — cleans melt filter screens and filter cartridges in PET, PP, and PA lines

-

⚙️ Extrusion Tooling Maintenance — suitable for die heads, gear pumps, and screen changers

-

🧵 Chemical Fiber Equipment — gentle cleaning for micron-level precision tools

-

🔧 Maintenance & Service Centers — standardized, automated solution for multiple clients and contaminant types

📞 Request a Custom Engineering Quote

To design your custom vacuum pyrolysis furnace, please provide:

-

Filter dimensions (diameter & height)

-

Contaminant type (e.g., PET, PA, HDPE)

-

Required cleaning capacity (units per cycle)

-

Installation environment / voltage requirements

Contact Technical Sales

📱 WhatsApp: +86-19106101572

📧 Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

PLC-Controlled Vacuum Cleaning Oven for Extrusion Tools — Fully Automatic Polymer Removal

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Melt Pipes — Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Screws — Automatic Polymer Removal Oven