Vacuum Pyrolysis Cleaning Oven for Cleaning Die Heads / Breaker Plates — Fully Automatic Polymer Removal Furnace

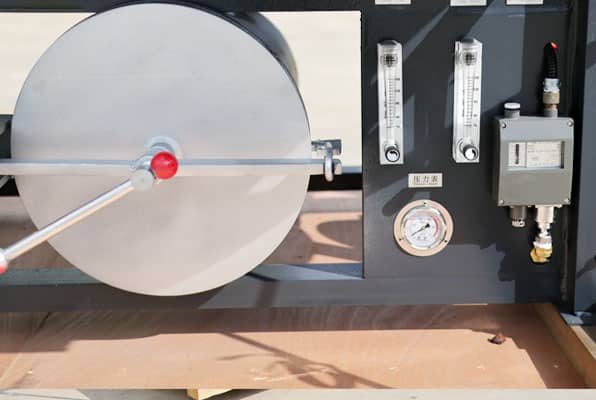

The Ruiyuan Vacuum Pyrolysis Cleaning Oven provides automated, high-efficiency cleaning for die heads, breaker plates, and extrusion components. Operating under −0.085 MPa vacuum and up to 450 °C, it removes polymer and carbon residues through controlled melting, pyrolysis, and oxidation. Designed for precision tools, it offers exceptional cleanliness, accurate temperature control, and low energy consumption.

Get Your Customised Product

🧴 Vacuum Pyrolysis Cleaning Oven for Die Heads & Breaker Plates | PLC-Controlled

🧭 Product Overview

The Vacuum Cleaning Oven for Cleaning Filters is an advanced vacuum pyrolysis cleaning system engineered for the automatic removal of polymer residues from filters and precision metal components.

It operates in a fully enclosed vacuum chamber, utilizing an electrically heated system to perform a three-phase cleaning process (Melting → Pyrolysis → Oxidation).

This ensures complete polymer decomposition while preserving the integrity of metal parts.

Ideal for plastic extrusion, nonwoven fabric, and chemical fiber production, the system provides residue-free, smooth surfaces and exceptional energy efficiency.

💡 Key Benefits for Buyers

-

✅ Fully automatic cleaning cycle — PLC-controlled operation, no manual supervision needed

-

✅ High thermal efficiency (≥98%) — saves energy and reduces operating costs

-

✅ Precise PID temperature control — ensures gentle, uniform heating without damage

-

✅ Residue-free, smooth surface — restores full filtration and operational performance

-

✅ Compact, durable design — suitable for factories and maintenance workshops

-

✅ Eco-friendly operation — closed vacuum chamber with exhaust scrubber for clean air release

⚙️ Product Features

-

Heating Method: Electric heating under vacuum conditions

-

Ultimate Vacuum: −0.085 MPa

-

Maximum Temperature: 450 °C

-

Temperature Control: PLC/PID system with real-time thermocouple feedback

-

Cleaning Phases: Melting → Pyrolysis → Oxidation (fully automatic)

-

Thermal Efficiency: ≥98% with high-grade insulation materials

-

Chamber Construction: Fully welded stainless-steel vacuum chamber with condensate collector

-

Safety System: Over-temperature protection, vacuum interlock, air purge, and auto shutdown

-

Optional: Water scrubber for gas and condensate purification

📊 Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Vacuum Cleaning Oven for Cleaning Filters |

| Ultimate Vacuum | −0.085 MPa |

| Heating Method | Electric heating |

| Maximum Temperature | 450 °C |

| Temperature Control | PLC/PID with thermocouple feedback |

| Thermal Efficiency | ≥98% |

| Cleaning Process | Melting → Pyrolysis → Oxidation |

| Structure / Material | All-welded stainless-steel vacuum chamber |

| Standard Voltage | 380 V / 50 Hz (customisable) |

| Typical Applications | Filter cleaning, mould head cleaning, extrusion part maintenance |

| Safety & Monitoring | Over-temperature protection, vacuum lock, exhaust scrubber system |

🔬 Working Principle

I. Melting Phase

Parts are gently heated to 320 °C under vacuum. Polymer residues melt and flow into the collector tray.

II. Pyrolysis Phase

Remaining polymers are pyrolyzed under vacuum, and gases are treated through a water scrubber, collecting condensates safely.

III. Oxidation Phase

Residual carbon and polymer traces are oxidized in a controlled air environment, leaving filters completely clean and ready for reuse.

🏭 Applications & Case Scenes

-

🧩 Filter cleaning — removes polymer and carbon buildup for full filtration recovery

-

⚙️ Mould and die maintenance — restores metal precision without abrasion

-

🧵 Extrusion and injection tool cleaning — ideal for plastic and nonwoven industries

-

🔧 Workshop & lab use — compact and reliable for routine maintenance

📞 Request a Quote

Provide your filter dimensions, contamination details, and cleaning requirements, and our engineering team will design a custom vacuum cleaning oven tailored to your production setup.

Contact Technical Sales

📱 WhatsApp: +86-19106101572

📧 Email: sabbir@cnryan.com

Related products

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for Extrusion Moulds — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for the Film Industry — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Oven for the Plastics Industry — Fully Automatic Polymer Removal System

-

Vacuum Cleaning Furnace

Vacuum Cleaning Furnace for Cleaning Melt Pipes — Automatic Polymer Removal System